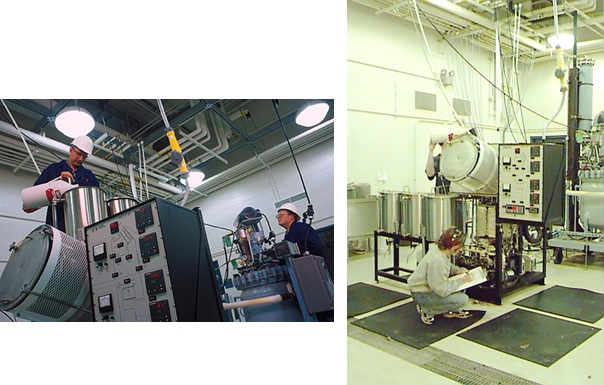

| Myers 15 molecular distillation unit |

|

The Myers ROTOR 15 Centrifugal Distillation System is a complete distillation system optimized for single stage plant operation. The unit which takes up minimal floor space, includes all pumping, heating, vacuum generating and control equipment in one complete package. In addition to power, low pressure air, and water, the only additional inputs needed for use are suitable storage tanks for feed stock, distillate and residue, plus cooling media for the trap.

The ROTOR 15 is designed for throughputs up to 80 pounds/hr (36 kg/hr) depending on feed material characteristics. The major advantages of the ROTOR 15 Molecular Still include: high product percentage yield, elimination of color bodies and odor fractions, and minimized thermal hazard (a necessity for heat sensitive compounds). The unit is designed to continuously distill thermally sensitive compounds at pressures ranging from .050 Torr to Atmosphere. The combination of low pressure, large surface area, and low residence time on the heated spinning rotor, not only reduces thermal hazard to the distillation product but also reduces the energy input required to run the system.