This page has been archived and is being provided for reference purposes only. The page is no longer being updated, and therefore, links on the page may be invalid.

Read the magazine story to find out more. |

|

|

Researchers Develop New Glue from Corn

By Jan SuszkiwSeptember 1, 2009

After the oil is extracted from corn germ meal, the corn germ is typically fed to poultry and other livestock animals. But a new, value-added use could be on tap for this “leftover,” thanks to studies by an Agricultural Research Service (ARS) scientist in Peoria, Ill.

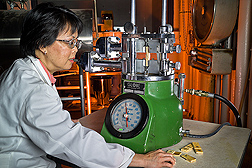

There, at the agency’s Plant Polymer Research Unit, chemist Milagros Hojilla-Evangelista has determined that corn germ can be used as a protein extender for plywood glues, potentially opening the door to a new market for the agricultural byproduct. Glue extenders reduce the amount of main binder, or resin, used in such glues and enhance their adhesive action.

The conventional extender for most plywood glues is industrial-grade wheat flour, according to Hojilla-Evangelista. However, she has sought to expand the list of agricultural extenders in the event glue manufacturers needed a comparable alternative—for example, because of a spike in wheat-flour prices or drop in supply.

Drawing on earlier work with soy-flour-based glues, Hojilla-Evangelista devised a corn-germ formulation for use in sprayline coating, a procedure that applies a liquid adhesive to wood surfaces using overhead nozzles.

In tests, she applied the corn-germ-based glue to one side of 12-inch by 12-inch southern pine veneers, then hot-pressed them following industry-standard conditions to produce three-ply panels. Her analysis of the material found the bonding strength of the corn-germ-based glue to be similar to that of the wheat-flour-based formula. Its viscosity and mixing properties also compared well, adds Hojilla-Evangelista, who first reported the findings in June 2008 at the Corn Utilization and Technology Conference in Kansas City, Mo.

Her focus now is increasing the amount of corn germ used in the glue to try and reduce the amount of resin needed, which would potentially cut manufacturing costs.

Read more about this research in the September 2009 issue of Agricultural Research magazine.

ARS is the principal intramural scientific research agency of the U.S. Department of Agriculture.