| Page 3 |

|

|

1 - Compressed Gas Cylinder Safety

2 - Page 2 3 - Page 3 4 - Page 4 |

HOME

HOME |

![]() Compressed Gas in Quicktime Movie

Compressed Gas in Quicktime Movie

RunningTime: 6 minutes

When transporting gas cylinders, use an appropriate hand truck and strap the cylinder down. Never drag or roll cylinders. Leave the valve cover cap on until the cylinder is secured in its area of intended use.

| Gas cylinders must be secured at all times to prevent tipping. |

Cylinders may be attached to a bench top, individually to the wall, placed in a holding cage, or have a non-tip base attached. Chains or sturdy straps may be used to secure them.

Always read the label!!

If leaking cylinder is discovered, move it to a safe place (if it is safe to do so) and inform Bill Shaben. You should also call the vendor as soon as possible.

Under no circumstances

should any attempt be made to repair

a cylinder or valve.

Standard cylinder-valve outlet connections have been devised by the Compressed Gas Association (CGA) to prevent mixing of incompatible gases. In general, right-handed threads are used for non-fuel and water-pumped gases, while left-handed threads are used for fuel and oil-pump gases. To minimize undesirable connections, only CGA standard combinations of valves and fittings should be used in compressed gas installations; the assembly of miscellaneous parts should be avoided. The threads on cylinder valves, regulators and other fittings should be examined to ensure they correspond and are undamaged.

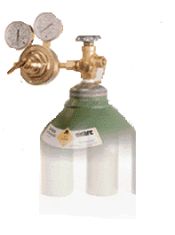

Cylinders are equipped with either a hand wheel or stem valve. For cylinders equipped with a stem valve, the valve spindle key should remain on the stem while the cylinder is in service. Only wrenches or tools provided by the cylinder supplier should be used to open or close a valve. At no time should pliers be used to open a cylinder valve. Some valves may require washers; this should be checked before the regulator is fitted.

Cylinder valves should be opened slowly. Oxygen cylinder valves should be opened all the way. Open up the oxygen cylinder valve stem just a crack. Once the needle on the high pressure gauge has stopped, open up the valve all the way. This back-seats the valve. Oxygen cylinders must have the valve opened up all the way because of the high pressure in the cylinder. There is a back-seating valve on the oxygen cylinder. This prevents the high-pressure gas from leaking out through the threaded stem.

When opening the valve on a cylinder containing an irritating or toxic gas, the user should position the cylinder with the valve pointing away from them and warn those working nearby.

Cylinders containing flammable gases such as hydrogen or acetylene must not be stored in close proximity to open flames, areas where electrical sparks are generated, or where other sources of ignition may be present.

Cylinders containing acetylene shall never be stored on their side.

An open flame shall never be used to detect leaks of flammable gases. Hydrogen flame is invisible, so "feel" for heat. One common practice is to use a natural bristle broom to "sweep" the air in front of you. All cylinders containing flammable gases should be stored in a well-ventilated area.

Oxygen cylinders, full or empty, shall not be stored in the same vicinity as flammable gases. The proper storage for oxygen cylinders requires that a minimum of 20 feet be maintained between flammable gas cylinders and oxygen cylinders or the storage areas be separated, at a minimum, by a fire wall five feet high with a fire rating of 0.5 hours. Greasy and oily materials shall never be stored around oxygen; nor should oil or grease be applied to fittings.

| Regulators are gas specific and not necessarily interchangeable! Always make sure that the regulator and valve fittings are compatible. |  |

If there is any question as to the suitability of a regulator for a particular gas, call your vendor for advice. After the regulator is attached, the cylinder valve should be opened just enough to indicate pressure on the regulator gauge (no more than one full turn) and all the connections checked with a soap solution for leaks.Never use oil or grease on the regulator of a cylinder valve.

The following rules should always be followed in regards to piping:

- Copper piping shall not be used for acetylene.

- Plastic piping shall not be used for any portion of a high pressure system.

- Do not use cast iron pipe for chlorine.

- Do not conceal distribution lines where a high concentration of a leaking hazardous gas can build up and cause an accident.

- Distribution lines and their outlets should be clearly labeled as to the type of gas contained.

- Piping systems should be inspected for leaks on a regular basis.

- Special attention should be given to fittings as well as possible cracks that may have developed.

A cylinder should never be emptied to a pressure lower than 172 kPa (25 psi/in2) (the residual contents may become contaminated if the valve is left open). When work involving a compressed gas is completed, the cylinder must be turned off, and if possible, the lines bled.

Empty and full cylinders should be stored in separate areas.

Where the possibility of flow reversal exists, the cylinder discharge lines should be equipped with approved check valves to prevent inadvertent contamination of cylinders connected to a closed system. "Sucking back" is particularly troublesome where gases are used as reactants in a closed system. A cylinder in such a system should be shut off and removed from the system when the pressure remaining in the cylinder is at least 172 kPa (25 psi/in2). If there is a possibility that the container has been contaminated, it should be so labeled and returned to the supplier.

Liquid bulk cylinders may be used in laboratories where a high volume of gas is needed. These cylinders usually have a number of valves on the top of the cylinder. All valves should be clearly marked as to their function. These cylinders will also vent their contents when a preset internal pressure is reached, therefore, they should be stored or placed in service where there is adequate ventilation.

Always use safety glasses (preferably with a face shield) when handling and using compressed gases,especially when connecting and disconnecting compressed gas regulators and lines. |  |

All compressed gas cylinders, including lecture-size cylinders, must be returned to the supplier when empty or no longer in use.

| << Previous 1 2 [3] 4 Next >> |