| Manure Project |

|

Phosphorus Recovery from Livestock and Municipal Waste Streams: ARS research scientists developed a patented treatment process, called Quick Wash, for extraction and recovery of phosphorus from poultry litter and pig manure solids, but research has shown that the approach is equally effective with municipal biosolids. The quick wash process generates two products: 1) washed solid residue, and 2) concentrated recovered P material. USDA granted an exclusive license to Renewable Nutrients, LLC to commercialize the Quick Wash®.

Resources:

https://www.youtube.com/watch?v=VOq2mGh24js

https://www.youtube.com/watch?v=AvSDVnDWzxk

Phosphorous recovery 2017 presentation... (eXtension)

Process for Removing and Recovering Phosphorus... (PDF)

From a PI’s Perspective: How We Made a T2 Success... (PDF)

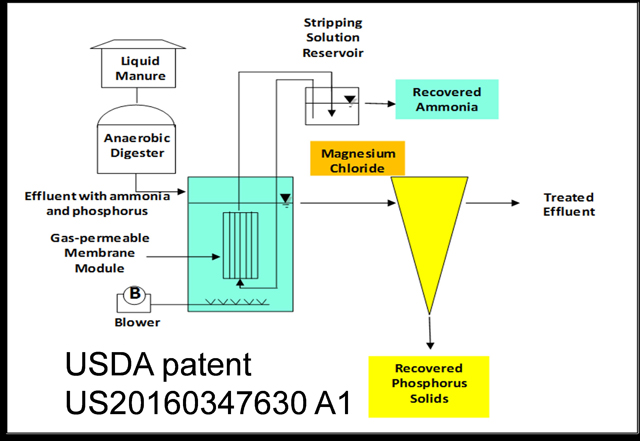

Enhancing Recovery of Ammonia Using Gas-Permeable Membranes: The new system allows capture and recovery of ammonia from livestock wastewater. Using low-rate aeration instead of alkali chemicals, recovery efficiencies were 96-98% while costs were reduced 70%.

Resources:

Technology showcase ... (PDF)

Ammonia Recovery from Digested Swine Manure...(PDF)

Recycling Ammonia Emissions as Fertilizer...(ARS magazine article)

Removal and Recovery of Amm. from Swine Manure...(PDF)

US Patent: Systems and Methods for Reducing Ammonia Emissions...(PDF)

Submerged NH3 trapping manifold...(Video)

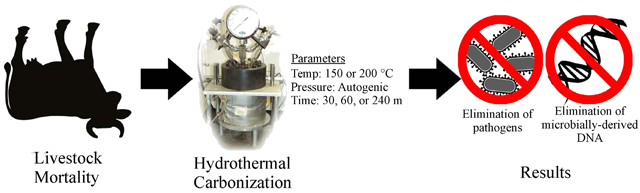

Hydrothermal carbonization (HTC) for waste treatment and nutrient recovery: Agricultural wastes such as livestock mortalities can be safely treated with HTC to kill pathogens and destroy antibiotic resistance genes. Since the majority of nitrogen, phosphorous, calcium and magnesium remained integrated within the hydrochar material, the recovered hydrochar can be used as a plant fertilizer.

Resources:

Hydrothermal carbonization of food waste... (PDF)

Hydrothermal carbonization of livestock mortality... (PDF)

HPNS - High Performance Nitrifying Sludge: The HPNS technology developed by ARS allows rapid and effective nitrification of high-ammonium concentration livestock and municipal wastewaters under low temperatures.

Resources:

Technology showcase ... (PDF)

US Patent: High Performance Nitrifying Sludge ... (PDF)

Novel anammox bacteria for wastewater treatment: The novel bacterial strain Brocadia caroliniensis is useful for the treatment of wastewater having undesirable levels of ammonia, including agricultural, industrial, or municipal wastewaters.

Resources:

Technology showcase ... (PDF)

US Patent: Anammox bacterium isolate ... (PDF)

Single-tank deammonification ... (PDF)

Anammox Immobilized in PVA Pellets... (PDF)

Recovery of Ammonia and Production of High-grade Phosphates From Animal and Municipal Effluents: The technology recovers ammonia and phosphorus from liquid effluents and produces phosphorus bio-minerals similar to the very-high phosphate grade commercial fertilizers favored by the fertilizer industry. USDA (ARS OTT) seeks a commercial partner to develop and market this invention (Docket 83.15)

Resources:

Recovery of N and phosphate minerals from animal effluents… (PDF)

Recovery of N and phosphate minerals from municipal effluents… (Abstract)

Waste-to-Worth 2017 presentation (eXtension)

Water Purification System For Space Exploration: Deammonification process uses USDA discovered microorganisms anammox Brocadia caroliniensis and HPNS nitrifiers. They were successfully tested by Pancopia Inc. (licensee) in NASA SBIR projects for purification of space wastewater.

Resources:

ARS Blog: H2O in Space: Waste Not, Want Not

CRADA with Pancopia… (Slide Summary)

Pancopia Inc… http://www.pancopia.com/projects/

FLC 2017 Project of the Year (Water purification system for space) (Award)

NASA Success Story: … High Performance Water Recycling System for Space Exploration

FLC National Award for Excellence in Technology Transfer : … Purification and Recycling Wastewater in Space and Decentralized Wastewater Systems Video

.jpg)

Recovery of Amino Acids (Proteins) and Phosphorus from Manure: A novel method for extraction and recovering amino acids and phosphorus from manure has been developed. This could be a potential new revenue stream from wastes. A patent application has been filed by ARS (USDA Docket 80.15).

Resource:

Waste-to-Worth 2017 presentation (eXtension)

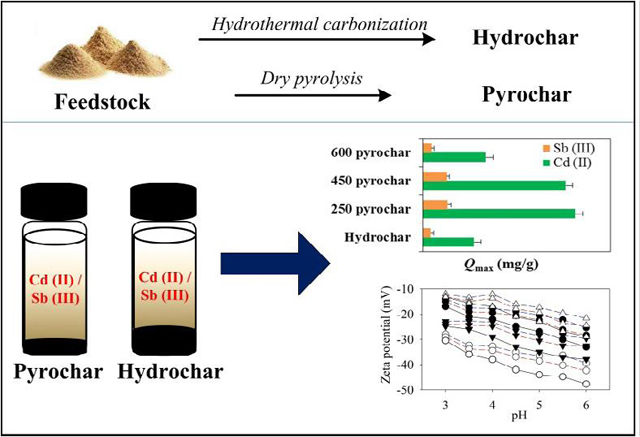

Removal of environmental pollutants with biochar and hydrochar: Activated and non-activated biochar (pyrochar) and hydrochar made from several feedstocks (swine manure, chicken litter, hickory, and peanut hulls) can remove antimony, arsenic, copper, cadmium, and lead from water. Biochars are also able to sorb pesticides and thereby reduce contamination of water resources.

Resources:

Removal of antimony (III) and cadmium (II) ... (PDF)

Kinetics and energetics of producing... (PDF)

Variation in sorption of propiconazole ... (PDF)

Sorption of four hydrophobic ... (PDF)

Removing pharmaceutical personal care products (PPCPs) from water with hydrochar: ARS scientists and university collaborators reported that hydrochars made from hydrothermal carbonization of swine manure and chicken litter have high sorption capacity for both polar and non-polar PPCPs. These hydrochars can be used as an environmental sorbent to remove PPCPs from water.

Resources:

New evidence for high sorption ... (PDF)

Properties of animal-manure based hydrochars... (PDF)

Recovery of Ammonia from Air in Poultry Barns: The ammonia recovery modules containing gas-permeable membranes are placed inside the poultry barns hanging from the roof and close to the litter, with ammonia concentrator tanks outside the barns.

Resources:

Research in Poultry Wins…. (UMES Ingenuity Magazine)

The Delmarva Farmer… (Research project)

Recovery of Ammonia from Poultry Litter… (PDF)

US Patent: Gaseous Ammonia Removal System ... (PDF)

Efficient treatment of ammonia, odor, pathogens and phosphorus in 3rd generation manure treatment technology: ARS Scientists at Florence, South Carolina together with business and university cooperators demonstrated and verified a 3rd generation wastewater treatment system (US Pat. 7,674,379) for swine manure that met one of the strictest environmental standards in the world at reduced cost.

Resources:

Generation 3 Final Technical Performance Report...(PDF)

Gen 3 Improved Solid-Liquid Separation of Diluted Swine Manure ... (PDF)

More information on 3rd , 2nd and 1st generation systems development

PBS Series: America's Heartland: Turning Hog Waste into Environmentally Friendly Fertilizer

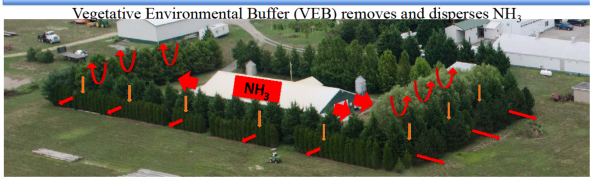

A vegetative environmental buffer (VEB): A VEB surrounding a broiler house can substantially reduce downwind ammonia concentration by dispersion and even removed 22% of emitted ammonia to biomass.

Resources:

Enhanced Dispersion and Removal of Ammonia Emitted from a Poultry House with a Vegetative Environmental Buffer.(PDF)

Swine odor removal using biochar: Commercial biochar can be used to reduce both H2S and odorous VOCs from swine manure with the potential of recycling the spent biochar for soil health improvement after its use.

Resources:

Efficacy of Different Biochars... (PDF)

Pilot-Scale H2S and Swine Odor Removal ... (PDF)

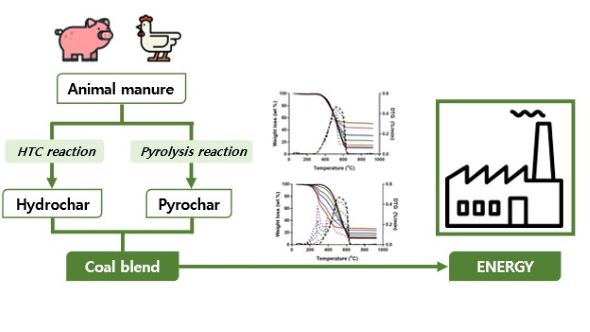

Animal manure and other agricultural residuals for energy applications: Animal manure can be converted to biochar or hydrochar which can be used for power generation by mixing with fossil coals. Other agricultural residuals can be used as feedstocks to produce liquid ethanol via combination of gasification and syngas fermentation techniques.

Resources:

Combustion Behavior of Animal-Manure-Based Hydrochar and Pyrochar.. (PDF)

Production of Ethanol from Livestock, Agricultural, and Forest Residuals... (PDF)

Potential use of earthworms and plastichars for enhanced bioremediation: Plastichars produced from co-pyrolyzing animal manure and plastic wastes can be biologically activated with earthworms to fight plastic pollution in soil.

Resources:

Potential use of earthworms... (PDF)

Biochar and earthworms... (PDF)

Earthworms increase the potential... (PDF)

Theoretical framework for predicting reactor pressure in designing hydrothermal carbonization reactor systems: Hydrothermal carbonization (HTC) reactor employs high pressure and temperature for converting wet biomass feedstock such as swine manure into value-added products. Because of the high reactor pressure, it is important to predict the reactor pressure for safety and material requirements. A step-by-step procedure was developed to accurately predict design HTC reactor pressure for different biomass feedstocks and design reactor temperatures.

Resources:

Theoretical framework for estimating... (PDF)

Comparitive studies on water- and vapor-based... (PDF)

Sub- and near-critical hydrothermal... (PDF)