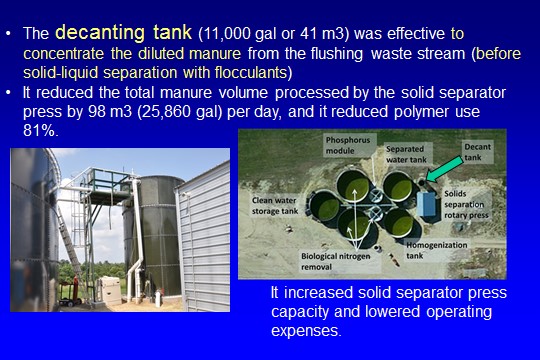

| Efficient treatment of ammonia, odor, pathogens and phosphorus in 3rd generation manure treatment technology. New or expanding swine operations in North Carolina are required to meet one of the strictest environmental standards in the world. These standards include emissions of ammonia and odor; the release of pathogens; and nutrient and heavy metal contamination of soil and groundwater. Scientists at ARS-Florence, SC together with industry and university cooperators demonstrated and verified a 3rd generation wastewater treatment system for swine manure (US Pat. 7,674,379) that could meet the environmental standards at reduced cost. Additional goals included replacement of the existing lagoons, and efficient performance when installed in larger swine farms. The technology was demonstrated full-scale on a farrow-to-finish swine farm that produced 30,450 hogs per year and generated 75,000 gallons of manure per day. The technology separated solids in the flushed manure with settling and polymer flocculants; subsequently, the ammonia nitrogen was treated with a new nitrifying bacteria adapted to cold temperatures (US Pat. 8,445,253); and lastly, the soluble phosphorus was recovered and the effluent disinfected. All major goals in this demonstration were successfully accomplished; the 3rd generation treatment process met the criteria identified in the referenced performance standards. Collectively this treatment process significantly reduces the potential for emissions of odor and ammonia, and the transfer of nutrients and pathogenic bacteria to surface and groundwater in the drainage basin where the animals are grown on animal feeding operations. The treatment process also provides a mechanism and market for the solids that are separated. |

|||

|

|||

|

|||

Second-Generation Treatment System |

|||

|

Producers and Pigs Profit From Manure Management Process | ||

|

|||

|

|

||

Final Report (Full PDF) Development of a second-generation environmentally superior technology for treatment of swine manure in the USA. |

|||

|

|||

|

|||

| |

|||

|

On-Farm First Generation system: (Full PDF |

|

||

|

|

||

|

|||

ARS Home

» Southeast Area

» Florence, South Carolina

» Coastal Plain Soil, Water and Plant Conservation Research

» Docs

» Third Generation Treatment System