| Hops |

|

Hops (Humulus lupulus) have been around since ancient times and were usually found as decorative plants in gardens. Hops were used in brewing around 3,000 years ago, but were first cultivated in the 8th century in central Europe. They were first introduced into the Northeast from Europe in 1629 by the Massachusetts Company. By the mid-1800’s production in the US (mainly New York) increased to over 1 million pounds. By the 1920’s, hops were pushed out West due to disease pressure (powdery and downy mildew).

Hops are from the same family as Cannabis and the same subclass as stinging nettle. Hops are used in brewing for bittering, flavoring, and preservation (due to their antimicrobial properties). The cone (strobile) is the fruiting structure of the female plant and contains small, yellow lupulin glands.

These glands contain the alpha and beta acids, and the other oils which give hops their characteristic flavoring quality. There is relatively small market for non-brewing purposes such as natural antibiotic for animal feed and for the mite treatment Hopguard II.

There are 2 types of hops, aroma or flavor hops and bittering hops. The aroma or flavor hops are used to impart aroma and unique flavors into beer. The characteristics that are critically important to brewers are the aroma, color, and the chemical profile. The bittering hops are grown for the alpha acids (which are the soft resins responsible for bitterness). The primary concern of the bittering hops is the yield of alpha-acids. Historically, the US produced mostly bittering varieties and Germany produced mostly aroma varieties, however, the proportion of acreage in each category has essentially flipped due to the growth of craft beer.

Hop Industry

There are about 53,000 acres of hops in the US which is roughly 40% of the world acreage and production and 47% of the world alpha acid production. Hop production was a $636 million industry in 2019, $583 million in 2018, $591 million in 2017, $498 million in 2016, and $345 million in 2015. There are about 100 growers in the Pacific Northwest and the farms range from 100 to 4,000+ acres. This encompasses about 50,000 of the US acreages. The remaining acres spread throughout the US with about 2,000 of these in New York and Michigan. Germany is 2nd in production at about 36%. There has been tremendous growth in the US hop industry due to the surging craft beer industry.

Hop Production

Hops are grown in fields known as Hop Yards. Hops are the flowers (cones) found on a hop plant. The plant is a perennial vine that grows to 20 feet and is often tough and prickly and the leaves are deeply lobed. Industrial hops production requires a particular environment. Most major hops production occurs in a moist temperate environment with long daylengths. In the US that is concentrated in the Pacific Northwest. Typically, in the spring, the first flush of growth is removed to set the time for training later in the spring and for disease suppression. The training dates are variety specific. In the Pacific Northwest, the training date varies from late April to late May and it depends on the variety, the growth rate, and weather. They are grown with the use of a trellis with wires and ropes to support the bine growth.

The ropes are tied to the wire at the top of the trellis and anchored into the ground next to the plant. The wires are positioned in a way that when the rope is anchored it forms a “V”. The hop bines are trained to grow up the ropes. It is typical to train 3-4 bines per string and the bines are trained clockwise onto the string.

With this “V” positioning, the plant is able to get equal amounts of sunlight around the bines. Each season, the hops plant will grow new bines from the crown and the rhizomes. The cones will form high up in the plant. To maximize the yield, the bines need to grow to the top of the trellis and produce a plentitude of side arms to achieve the maximum number of nodes before flowering.

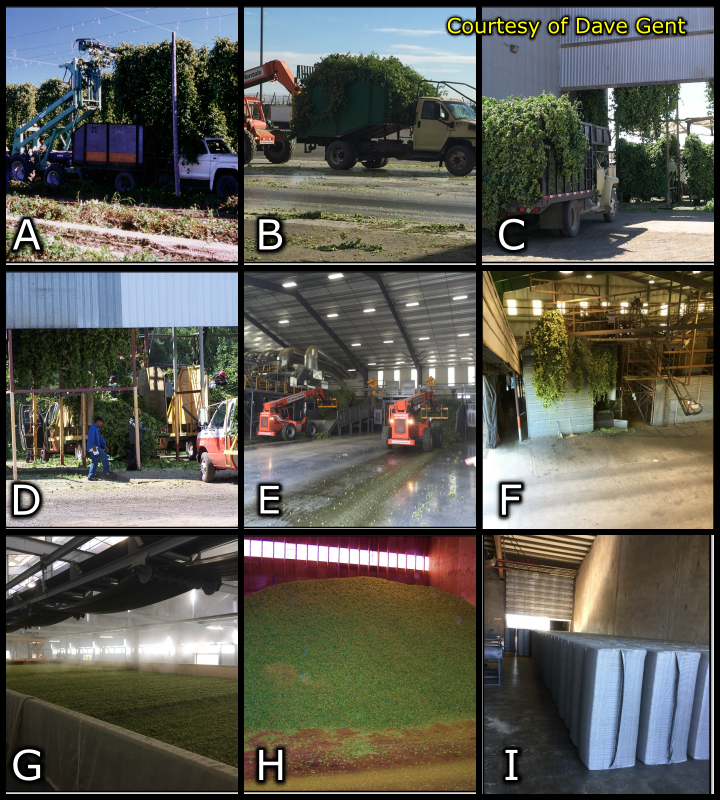

Hop Harvest

The hop harvest is the most labor intensive and high money aspect of hop production. Usually at the end of the summer, the cones are harvested. The bines and the ropes are cut at the base at about 3 feet from the ground and the ropes at the top of the trellis are cut (A). In the Pacific Northwest the picking machines are stationary and the harvested plants are brought to the picking facility (B, C, D, E, F). The cones are perishable and must be kiln dried (G) and once they are dried (H), they are stored in compressed bales (I) near 32oF until sold or processed. After harvest, the plants will die back and go dormant for the cooler season, and when it warms again, they will start producing bines and the cycle starts again.

Hops are not typically grown in Florida. The shorter days and higher temperatures are not optimal for hop growth. The shorter days will result in earlier flowering and lower harvests; however, it does aid in multiple harvests. This is the interest that has brought the idea of hops to Florida.

Hop Propagation

Hops can be propagated two ways. You can use the rhizomes or you can make a cutting from an actively growing plant. When using rhizomes, they are cut from the plant and planted horizontally into moist soil with the root side down. They typically take 1-2 weeks to start growing. Cuttings can also be made from an actively growing hop plant. Cuttings are how we propagate hops at our facility. The bines are cut from the plant (A). Each cutting is cut above the nodes creating a small stem with 2 leaves (B, C). One leaf is removed (D) and the cutting is dipped into rooting hormone (E) and placed into a prepared wet soil tray (F). Once all the cuttings are in the tray (G), the tray is placed in a greenhouse and covered with plastic for 2 weeks (H). During the 2 weeks, the plants are watered and/or misted with a spray bottle once a day. After the two weeks, the plastic can be removed and plants watered on a regular schedule. It will take a couple months before you have a usable plant that can be plated in the ground.

Current Work at USHRL in Ft. Pierce, FL

In 2017, we installed a trellis at our facility. We have a (1/4 acre) hop yard at our Picos Farm location with 8 hop varieties (Cascade, Centennial, Willamette, Nugget, Mt. Hood, Crystal, Zeus, and Chinook). Half of the hop yard has a 20 ft trellis and the other half has a 10 ft trellis each with 3-200 ft rows. Since Florida has shorter days, we have installed lights on both trellises.

A hurdle we faced was the cold dormancy period that is needed in hops production. To test if this is needed in Florida, we have half of our tall trellis being used as a vernalization experiment. The hops are grown in 30-gallon fabric pots. This gives us the ability to move the plant into a cooler for the dormancy period.

Every season, half of the potted plants are moved to a cooler for several months. The remaining plants are subjected to the mild Florida winters. The remaining hops plants in the hop yard are planted in-ground on raised soil beds. Each plant has its own irrigation emitter where water and fertilizer are sent to the plant.

Our hops are harvested using a Hops Harvester (A). The Hops Harvester is connected to a tractor and is used in the field. The bines are fed through the back of the harvester (B) and the cones are picked mechanically from the bine and fed through a set of conveyer belts and fans and leave through a shoot on the side to be collected in a box or a bin (C).The cones are then dried in an oast. An oast is a drying oven. The hops are placed onto screened racks and placed in the oast. The oast will circulate heated air around and dry the hops. Hops are dried to 10% moisture and then baled. We then use a Hops Baler (D) (from Hops Harvester) to bale the dried hops. The hops are baled, wrapped in burlap, and stored in a cold room.

Every year we have our hops analyzed for their oil, alpha, and beta contents. They are tracked season to season and by variety. The results of these tests are our way of knowing how the quality of our hops are in comparison to industry standards.

Selected Sources