| Fabrication Shop |

|

Fabrication Shop

Location

2150 Centre Ave. Building F

Fort CollinsColorado80526

Shop Supervisor

Horacio Garza

Agricultural Research Technician

Phone: 970-492-7497

Fax: 970-492-7408

e-mail: Junior.Garza@ars.usda.gov

Shop Area:

12,000 square feet of indoor workspace and storage.

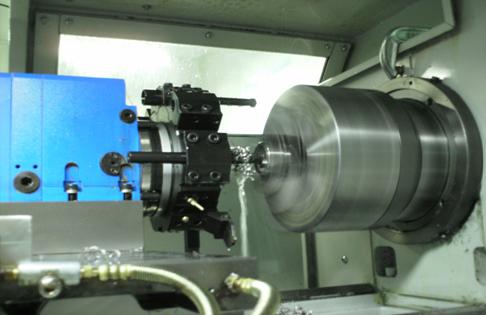

Machining

•• Set up for rapid production of very precisely machined parts.

•• CNC vertical tool room mill 25"x15"x21"

•• 8,000rpm spindle

•• 16-tool magazine

•• CNC tool room lathe

•• 15" swing

•• 2.18" spindle bore

•• 7.5 horsepower spindle drive

•• 20-3000rpm range

•• 8 tool turret

•• 36" bed

•• Vertical knee mill

•• Bench lathe

•• 11" swing, 24" bed

•• Engine lathe

•• 14.5" swing x 32" bed

•• Drill/Mill

•• 2 drill presses

•• Surface Grinder

Sheet Metal

•• Mechanical squaring shear-1/4"x6' capacity in A36 mild steel. 7/32" on 18-8 stainless steel.

•• Jump shear-42", 18 gauge A36 mild steel.

•• Finger Brake-22", 18 gauge A36 mild steel.

•• Pan brake-6', 18 gauge A36 mild steel.

•• Mechanical Press brake-60 ton x 12'-12 gauge

•• CNC plasma cutting system-4' x 4' table, 1" thick material capacity

Band Saws

•• 1--vertical 12" throat

•• 1--vertical 20" throat

•• 1--vertical 40" throat

•• 1--Horizontal 20" throat

Material handling

Capable of handling 4'?8' sections of sheet metal and 21' lengths of stock.

Can do large projects up to 12'?14'in dimension. (Large Door dimensions)

Forklifts:

1---2,300lb. Electric

1---4,000lb. Electric

1---4,000lb. Diesel

1---10,000lb. Diesel

Misc:

1---engine stand

1---engine hoist

1---Leveling fixture table 8.5'x14'

Chains, hooks, clevises boomers, plate dogs...

Welding:

MIG

TIG

Stick

Oxy/acetylene torch

300-amp plasma cutter

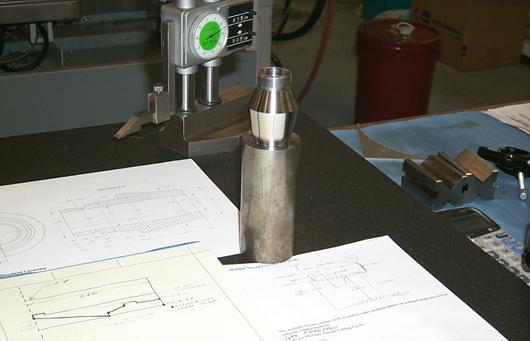

Engineering/Fabrication

Sample Projects

By: Paul Irvin

Theoretical tapered clutch designed for a tractor (2001) ColoradoStateUniversity for an undergraduate project

Sample from the shops CAD/CAM (computer aided design/computer aided machining) Program (BobCAD/CAM)

The program is used to draw mechanical parts 2D/3D, and generate G-Code, which is the alpha/numeric code that the computer on the CNC (computer numerically controlled) machine reads to cut the designed part.

Drop cone penatrometer: used to measure soil compaction. Built at CSU for Agricultural Engineering Professor, Dr. Paul Ayers (2000)

Soil Infiltration Cylinder-Designed by Phil Bacon, machining process/setup by Paul Irvin (built for USDA-WMR, 2003)

Micro-Precision Scales built for weighing small amount of water drainage from a soil column. Designed and built by Paul Irvin for Dr. Tim Green (USDA-ASR, 2005)

Laser-Point Frame: A frame that contains 10 laser diode modules spaced 10 cm apart on a tripod configuration. Devise is used to measure vegetation parameters, which are treated with statistics to determine the state of the vegetation. Built originally for Lisa Vanamberg and Mark Weltz (USDA-GPSR 2000). 7 units have been made to date and are constantly being engineered and fabricated.

Machining Processes

Turning

Chasing threads in a cap for a ball mill cylinder

PTO flange for a Chevy 4.3 liter v-6 engine. Used to drive a hydraulic pump for hydraulics on a hydrostatic tractor.

1" diameter Soil coring bit

Turned parts for ball mill assembly: Quality control.

Soil sample cups for mass sampling. Designed to fit a specific laboratory-measuring machine: Quality control.

Milling

Lifting bracket half for a Lysimeters monolithic soil-retaining tank.

Manual milling of a large chamfer on a lifting bracket, which is preparation for a multipass weldment designed to hold a 20,000 lb. Tensile loading.

Lifting eyelet used on lifting bracket.

3D milling capability demo of the Milltronics RH15 CNC vertical milling center.

RH15 CNC mill used here to drill lug clearance holes on an aluminum wheel spacer used for spacing out wheels on a tractor.

Wrench being cut for use on 5" nuts on large hydraulic cylinders.

Bolthole patter cut on a PTO flange.

Flutes and gullets being manually milled on soil coring bit

Sine plate work used in pocket milling sockets for an array of pockets used to house hold thermal sensors for calibration.

Sheet Metal Work

Hood for engine compartment on a high-clearance sprayer tractor.

Brackets for hydraulic cylinders and spray boom on a high-clearance sprayer tractor.

Coshocton flume made from 8 and 10 gage stainless steel.

Coshocton flume throat

Welding

Roll cage member on a High-Clearance Tractor

Monolithic tank temporary top.

Large Projects

Rocky Ford Colorado weighing Lysimeter outer retaining tank installation.

Finished Rocky Ford Lysimeter Monolithic soil tank.

Extracted soil core within the Monolithic tank.

Completed installation of Rocky Ford Lysimeter super structure.

High-clearance chemical application tractor.

High-clearance chemical application tractor.