This page has been archived and is being provided for reference purposes only. The page is no longer being updated, and therefore, links on the page may be invalid.

|

Food-Grade Starch Put to New Industrial Use

By Jan SuszkiwJanuary 14, 2005

A technique for changing the water repellency of plastic films using coatings of steam-jet-cooked starch has been developed by Agricultural Research Service scientists.

Among the reasons for using this process is to improve plastic's retention of water-based dyes and printing inks, such as those used on food labels, as well as to reduce buildup of static charge. Commercial polymers like polyethylene are hydrophobic, or water-repelling, until rendered otherwise (hydrophilic) with chemical reagents. But according to ARS scientists Fred Felker and George Fanta, coating such plastics with soluble starch--prepared by steam-jet cooking--could offer a cheaper, easier and safer alternative.

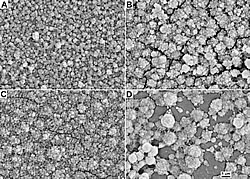

In studies since 2001 at the ARS National Center for Agricultural Utilization Research, Peoria, Ill., the scientists showed that tiny particles of starch comprising the one-micrometer-thick coating hold water in place, preventing it from beading and rolling off the plastic's surface. And if a film of polyethylene is thin enough, the scientists observed, the coating will temporarily change the film's shape when the coating dries.

The scientists made the hydrophilic coating as part of an ARS research effort at Peoria to develop new, value-added products from agricultural commodities, especially cornstarch. The U.S. supply of cornstarch--along with starches from rice, potato and other crops--often outpaces demand for the commodity, the researchers note in a published paper describing their invention.

Felker and Fanta are hoping the hydrophilic starch coating will nibble away at that surplus, either by making plastic films more water-friendly or by another novel application. One possible use: preventing the buildup of electrostatic charges, which may prove useful in plastic packaging used to wrap electronics equipment. The coating's water-friendly surface may also offer a way to make medical devices more compatible with the human body. Earlier this year, ARS obtained a patent (U.S. Patent 6,709,763) on the invention and is seeking to license it to a company that can explore such possibilities.

ARS is the U.S. Department of Agriculture's principal scientific research agency.